This story first appeared in issue #57 (fall 2015) of our Gravy quarterly. The author, Sheri Castle, writes and teaches cooking in Chapel Hill, North Carolina. She is a lover of mountains, farmers’ markets, and bourbon.

Thanks a Mint

My hometown secret

by Sheri Castle

You know those little individually wrapped butter mints that come with the check at a certain type of restaurant, perhaps the chain steakhouse where your aunts and uncles take you when you go to visit, a place that pegs the doneness of the meat with colored plastic picks? The mints that wait politely in a cut-glass bowl next to the register at the meat-and-three, where the implied offer is all you can carry but you retain yourself to a decorous two? Yes, those mints. You pop the first one in your mouth as you walk to the car and eat the second when you find it in the bottom of your cup holder a day or three later. The candy has a slight crisp crust on the outside, quickly melting on the tongue to a wonderfully smooth and creamy interior, like a tasty glob of buttercream frosting left out overnight.

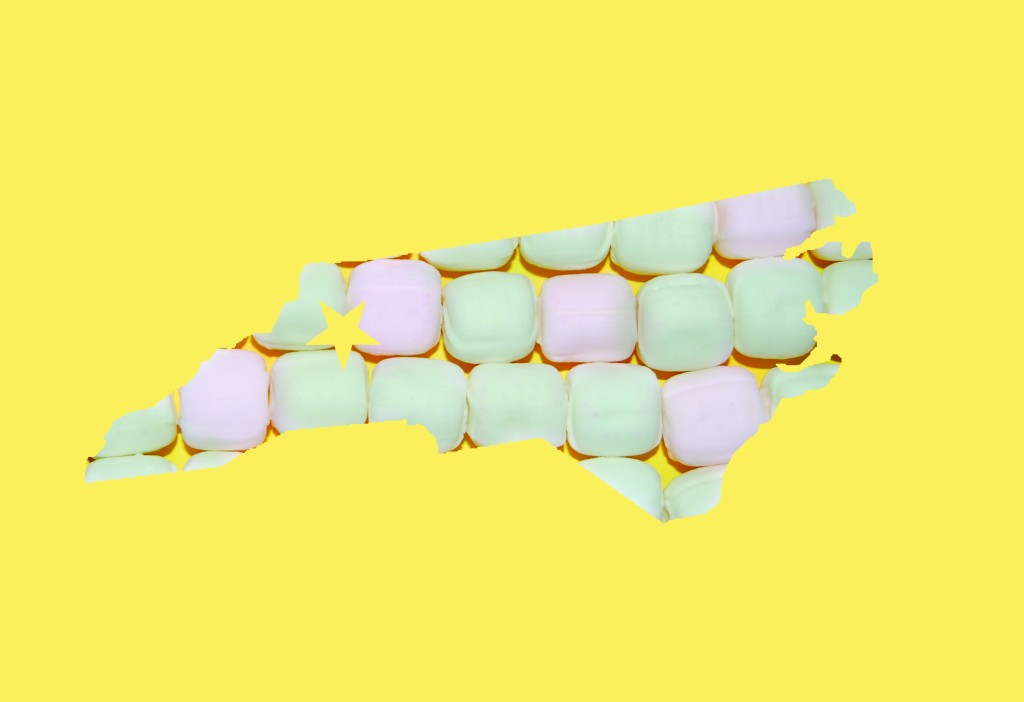

Hospitality Mints in my hometown of Boone, high in the Blue Ridge Mountains of Western North Carolina, makes a prodigious number of these mints. In a community curiously called Bamboo, across from the tiny private airstrip that the locals wryly call Bamboo International, the factory building on Candy Lane is nondescript. Around it, the air swirls with the scents of sugar and chocolate and mint.

Inside, 155 employees, almost all locals who have worked there for years, crank out as many as 10 million mints a day. Most of these are the soft, white, peppermint puffs. That’s more than 1 billion a year. Even in the days of mechanization, making mints is tedious. Each 2,500-pound batch takes nuanced adjustment and handwork while it cooks. Perfect mints demand merging and managing sugar, butter, time, and heat. Even on a winter day when employees have to climb on the roof to shovel off the weighty snow, the candy kitchen can soar to 120 degrees.

Hospitality Mints began as a family business in 1976. Founder Mitchell Minges started with a few copper kettles and a marble slab in the corner of the sauerkraut factory his family ran near downtown Boone. In 1988 they moved to the current location so they could increase capacity and refine their packaging. Each mint is individually wrapped in its own cocoon. Multiple patents protect the printing system that stamps custom logos and images onto every wrapper.

Four cordial women answer the customer service calls at the factory. Rarely a day goes by when someone doesn’t ring up only to say thanks and chat a bit. One caller recently ordered her own case of mints to keep at home, lest she be “banned for life from the Sizzler” for filling her purse each time she left after Sunday lunch.

Hospitality Mints sells to all 50 states and the better part of Canada. It never fails to charm and center me when I’m traveling and flip up the flap on my mint wrapper to see the words “Boone, North Carolina.” I’ve turned that bit of trivia into a bar trick. Each time I get a chance, I hover my hand over the unopened mints and tell my tablemates that I can intuit where those mints came from. Sometimes I go so far as to make a friendly wager. I’ve never made a meal of those mints, but I’ve eaten lunch off them more than once. How hospitable.